What Is a Centrifugal Pump?

- A centrifugal pump is a mechanical device that moves fluid by using rotational energy. Think of it like a water slide that spins—the spinning motion creates force that pushes the fluid outward and through pipes. These pumps are everywhere: in your home’s water system, swimming pools, irrigation systems, and countless industrial applications.

- Unlike other pump types that trap and squeeze fluid (called positive displacement pumps), centrifugal pumps use spinning motion to create flow. This makes them ideal for moving large amounts of low-viscosity fluids like water, chemicals, and oils.

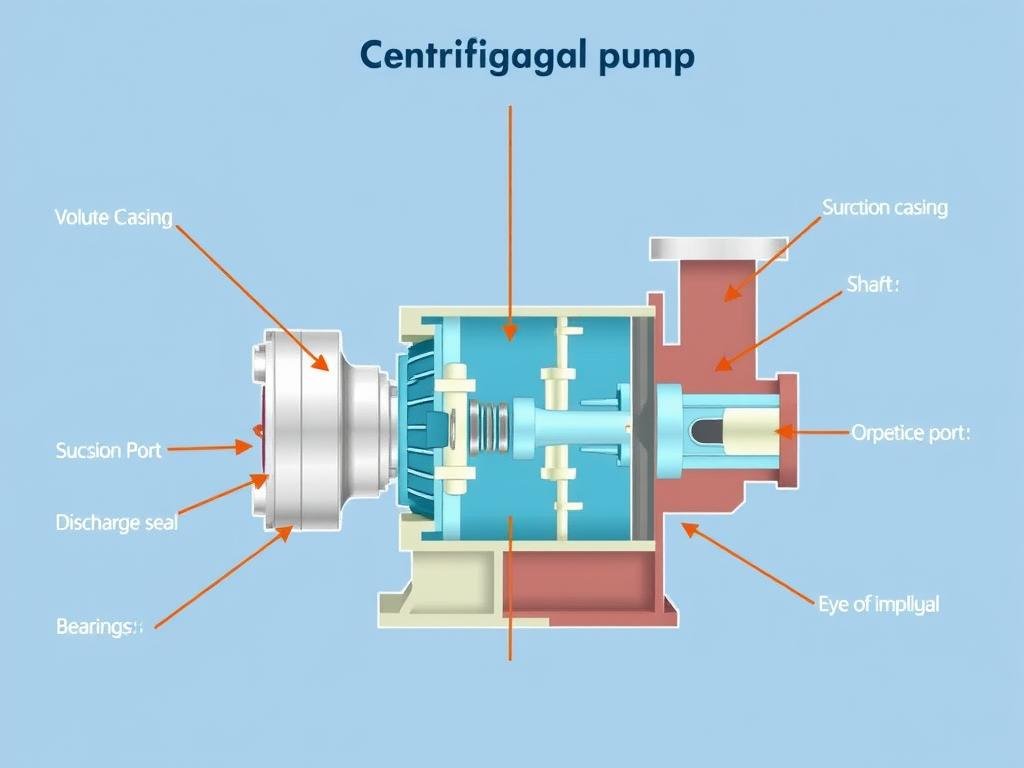

Parts of a Centrifugal Pump Diagram:

Let’s break down the main components you’ll see in any centrifugal pump diagram. Understanding these parts helps you grasp how the pump works as a whole.

Cross-sectional view of a centrifugal pump showing internal components

1). Impeller:

- The impeller is the heart of a centrifugal pump. This spinning wheel has curved blades that push the fluid outward when it rotates. Think of it like a pinwheel that, instead of being moved by air, moves the fluid around it. Impellers come in different designs depending on the pump’s purpose.

2). Casing:

- The casing is the outer shell that surrounds the impeller. It’s designed to collect the fluid thrown outward by the impeller and direct it to the discharge outlet. The most common type is called a “volute” casing, which has a spiral shape that helps convert the fluid’s speed into pressure.

3). Shaft:

- The shaft connects the impeller to the motor. It transfers the rotational energy from the motor to the impeller. The shaft needs to be strong enough to handle the power being transferred and is usually supported by bearings.

4). Suction and Discharge Ports:

- The suction port (or eye) is where fluid enters the pump. It’s typically located at the center of the impeller. The discharge port is where the pressurized fluid exits the pump after passing through the impeller and casing.

5). Bearings:

- Bearings support the shaft and allow it to rotate smoothly with minimal friction. They absorb the forces created during pump operation and help maintain proper alignment.

6). Mechanical Seal:

- This component prevents fluid from leaking along the shaft where it exits the pump casing. It’s like a special door that lets the shaft spin while keeping the fluid inside the pump.

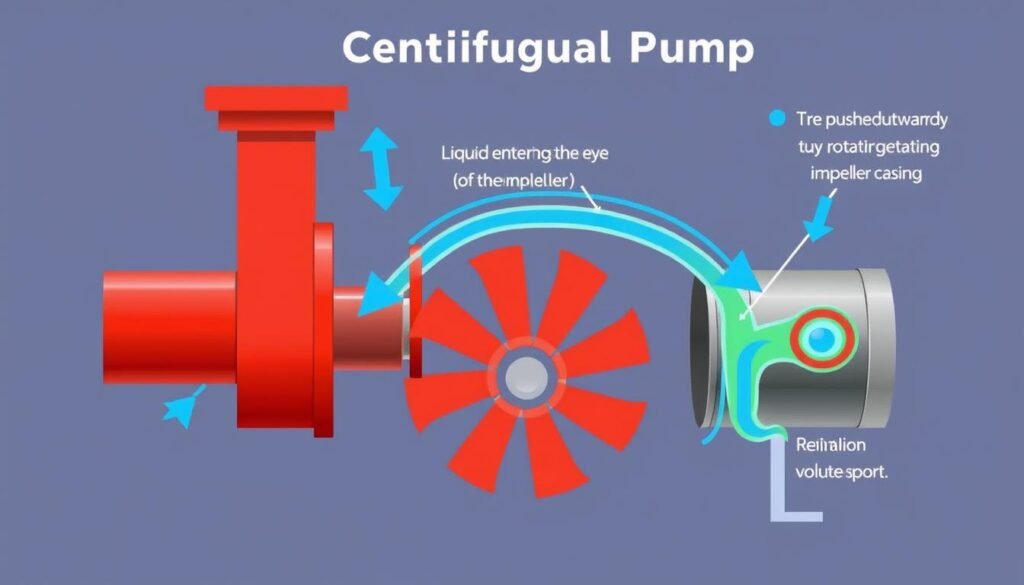

How a Centrifugal Pump Works?

Now that we know the parts, let’s see how they work together to move fluid. The process is simpler than you might think!

Flow path of liquid through a centrifugal pump

- The motor starts and turns the shaft, which rotates the impeller.

- As the impeller spins, it creates a low-pressure area at its center (the eye).

- This low pressure draws fluid in through the suction port.

- The fluid enters the eye of the impeller and gets caught between the impeller blades.

- The spinning impeller throws the fluid outward using centrifugal force.

- As the fluid moves outward, it gains speed and energy.

- The volute casing captures this fast-moving fluid and slows it down.

- As the fluid slows, its energy converts from speed (kinetic energy) to pressure.

- The pressurized fluid exits through the discharge port.

This continuous process creates a steady flow of fluid through the pump. The faster the impeller spins, the more fluid moves and the higher the pressure becomes.

Key Point: Centrifugal pumps must be “primed” before starting. This means filling the pump with fluid first, as they can’t pump air effectively. Unlike some other pump types, centrifugal pumps can’t start dry.

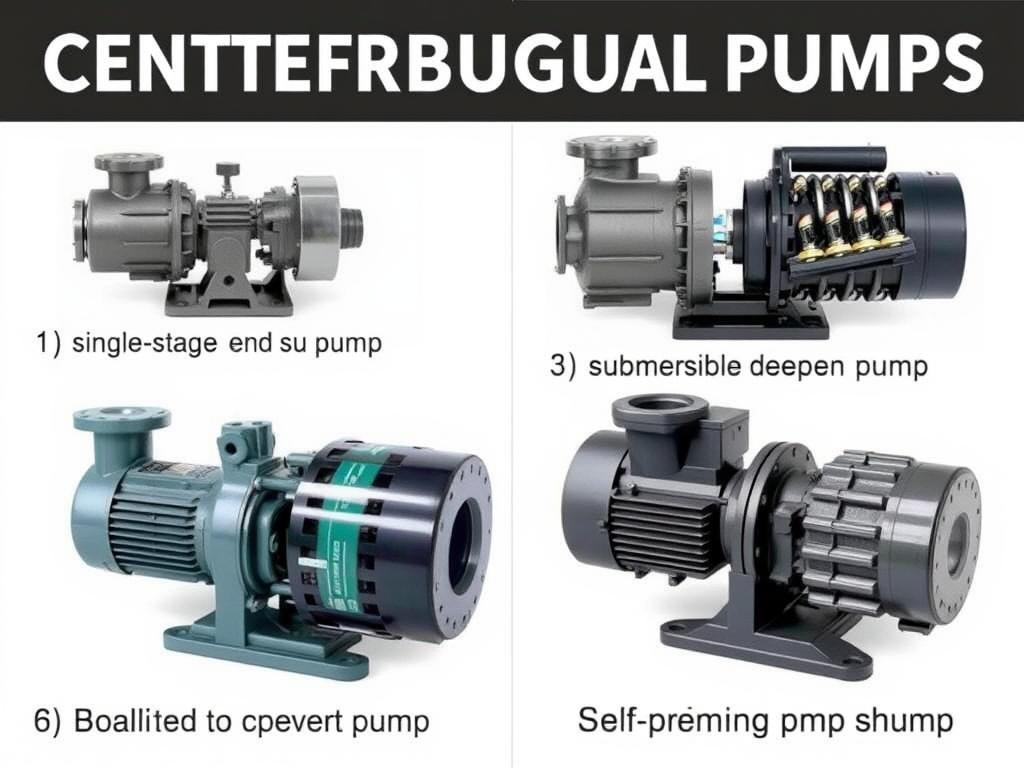

Common Types of Centrifugal Pumps:

Centrifugal pumps come in several varieties, each designed for specific applications. Here are the most common types you might encounter:

1). Single-Stage Pumps:

- These have one impeller and are used for low to medium pressure applications. They’re common in home water systems, swimming pools, and light industrial use.

2). Multi-Stage Pumps:

- These pumps have multiple impellers in series, creating higher pressures. They’re used in applications requiring high pressure, like high-rise building water supply or industrial processes.

3). Submersible Pumps:

- These are designed to operate underwater. The entire pump and motor assembly is submersible, making them ideal for wells, drainage, and wastewater applications.

4). Self-Priming Pumps:

- These special pumps can remove air from the suction line and pump, allowing them to restart without manual priming. They’re useful in applications where the pump might run dry occasionally.

Different types of centrifugal pumps for various applications

Common Applications of Centrifugal Pumps:

Centrifugal pumps are workhorses in many industries and everyday applications. Here’s where you might find them:

Home Use:

- Water supply systems

- Swimming pool circulation

- Garden irrigation

- Sump pumps for basement drainage

Industrial Applications:

- Chemical processing

- Oil refineries

- Power plants

- Food and beverage processing

Municipal Systems:

- Water treatment plants

- Wastewater management

- Flood control

- Irrigation systems

Centrifugal pumps in a water treatment facility

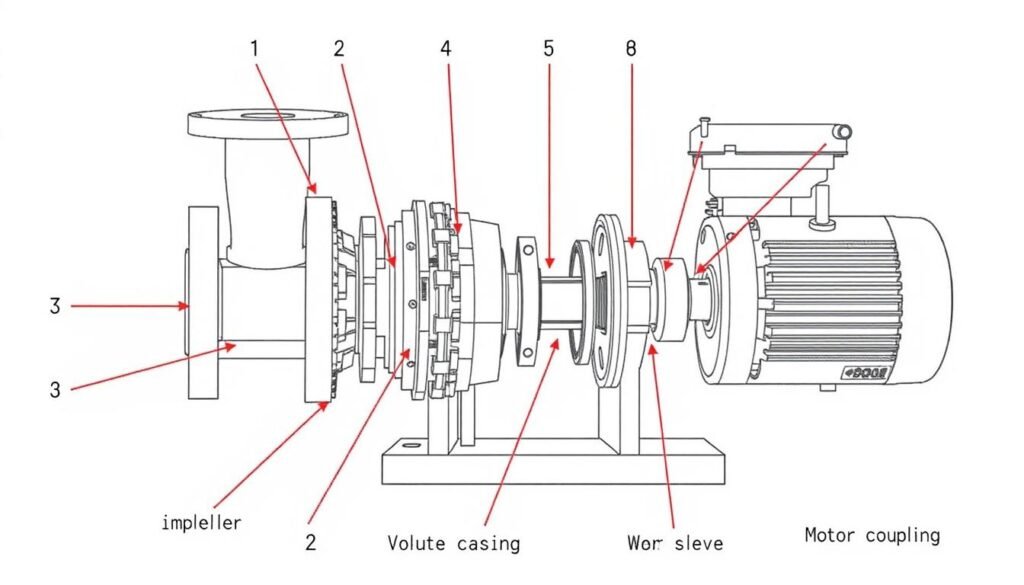

How to Read a Centrifugal Pump Diagram:

Understanding pump diagrams helps you identify parts, troubleshoot problems, and communicate with professionals. Here’s how to make sense of them:

Numbered centrifugal pump diagram with component callouts

Types of Diagrams You’ll Encounter:

1). Cross-Sectional Views:

- These show the pump as if it were cut in half, revealing all internal components. They’re useful for understanding how parts fit together and interact.

2). Exploded Views:

- These show all parts separated but in relative position to each other. They’re helpful for assembly and disassembly tasks.

3). Performance Curves:

- These graphs show how the pump performs under different conditions. They typically plot flow rate against pressure, power, or efficiency.

4). Piping and Instrumentation Diagrams (P&IDs):

- These show how the pump connects to the broader system, including valves, instruments, and control systems.

- Reading Tip: When looking at a pump diagram, start by identifying the impeller (usually at the center) and then work your way outward to understand how fluid flows through the system.

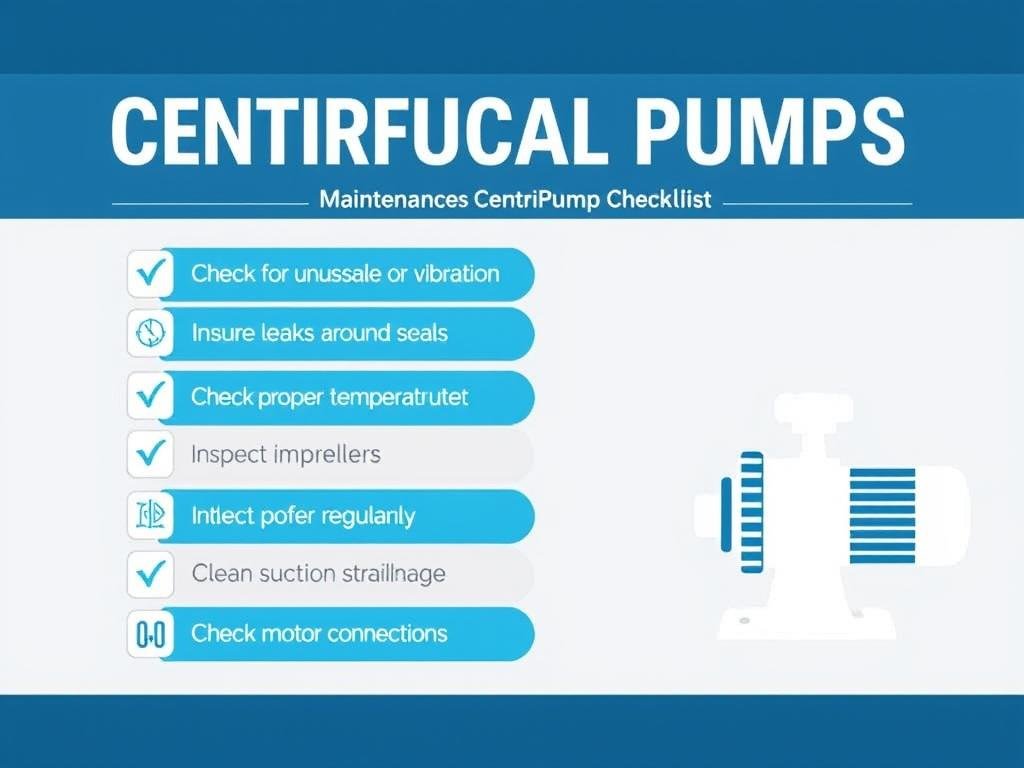

Basic Maintenance Tips:

Understanding centrifugal pump diagrams also helps with basic maintenance. Here are some simple tips to keep your pump running smoothly:

Centrifugal pump maintenance checklist

1). Regular Checks:

- Listen for unusual noises or vibrations

- Check for leaks around seals

- Monitor operating temperature

- Inspect suction and discharge pressure

2). Preventive Maintenance:

- Lubricate bearings according to manufacturer guidelines

- Check alignment between pump and motor

- Clean or replace filters and strainers

- Inspect impeller for wear or damage

Safety First: Always disconnect power before performing maintenance on a pump. Make sure the pump is cool and pressure is released from the system.

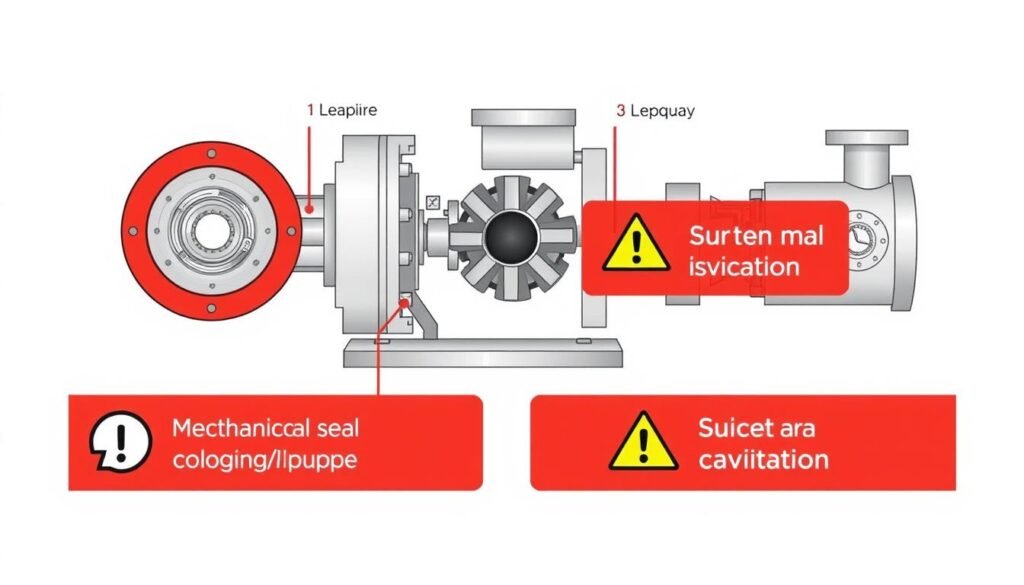

Common Problems and Troubleshooting:

Even the best centrifugal pumps can develop issues. Understanding the diagram helps identify where problems might be occurring:

| Problem | Possible Causes | Related Components |

| No or low flow | Air in system, clogged impeller, wrong rotation | Impeller, suction line |

| Excessive noise | Cavitation, worn bearings, misalignment | Impeller, bearings, shaft |

| Leakage | Worn seals, loose connections | Mechanical seal, gaskets |

| Overheating | Running dry, excessive load, poor ventilation | Motor, bearings |

Common problem areas in centrifugal pumps

One of the most common issues with centrifugal pumps is cavitation—when vapor bubbles form and collapse inside the pump due to low pressure at the suction side. This causes noise, vibration, and can damage the impeller over time. Proper installation and sizing help prevent this problem.

Conclusion:

Understanding centrifugal pump diagrams doesn’t have to be complicated. By recognizing the basic parts and how they work together, you can better understand these essential machines that keep fluids moving in countless applications. Whether you’re a homeowner trying to understand your water system, a student learning about fluid mechanics, or a technician starting in the field, this knowledge provides a solid foundation.

Remember that centrifugal pumps work by converting rotational energy into fluid movement and pressure. The impeller is the heart of this process, while the casing, shaft, and other components all play important supporting roles.

Frequently Asked Questions:

1). What’s the difference between a centrifugal pump and a positive displacement pump?

- Centrifugal pumps use rotational energy to move fluid and create pressure, while positive displacement pumps trap and force fluid through the system. Centrifugal pumps are better for high flow rates of low-viscosity fluids, while positive displacement pumps excel with high-viscosity fluids and precise flow control.

2). Why does a centrifugal pump need to be primed?

- Centrifugal pumps need liquid in them to start working properly. They can’t create enough suction to pull in liquid if they’re full of air. Priming fills the pump with liquid before starting, ensuring it can operate correctly. Some specialized “self-priming” pumps can remove air themselves, but standard centrifugal pumps cannot.

3). Can centrifugal pumps handle solids in the liquid?

- Some centrifugal pumps are designed to handle liquids containing solids. These are often called “slurry pumps” or “trash pumps” and have special impeller designs with wider passages to prevent clogging. Standard centrifugal pumps, however, work best with clean liquids.