Pump-motor shaft alignment is key to making industrial machinery work well and last long. It’s not just about following rules; it’s about making sure everything works together perfectly. When pumps and motors are aligned right, they use less energy and last longer.

But, if they’re not aligned, big problems can happen. Things like more wear and tear, overheating, and parts breaking down early. By paying attention to how shafts are aligned, I can keep my pumps and motors running smoothly. This is vital for any machine to perform its best.

Understanding Pump – Motor Shaft Alignment:

Exploring pump motor shaft alignment is key in mechanical systems. It’s about placing a pump and its motor just right next to each other. This ensures they work well together and don’t wear out too fast.

Knowing the right terms is important. Words like “coupling” help us see how things can go wrong. “Deviation” shows how far off things are from perfect alignment. “Angular misalignment” is when the angle is off, not just the distance. Learning these terms helps everyone talk the same language.

Common Causes of Misalignment:

Understanding the common causes of misalignment is key for keeping pump-motor systems running well. Factors like thermal expansion, foundation settling, and bad installation can cause misalignment. Over time, wear and tear also play a big part. These problems can lead to more vibration, which is a sign of misalignment.

Thermal expansion happens when parts get hot and move away from their perfect spot. Foundation settling changes the base of the equipment, causing misalignment. Bad installation can also make a system prone to misalignment from the start.

Vibration analysis is a great way to catch these issues early. By watching vibration levels, I can find misalignment problems before they get worse. Following standards like those from the American National Standards Institute (ANSI) makes vibration monitoring more effective. It helps avoid expensive downtime due to misaligned equipment.

Shaft Alignment Techniques:

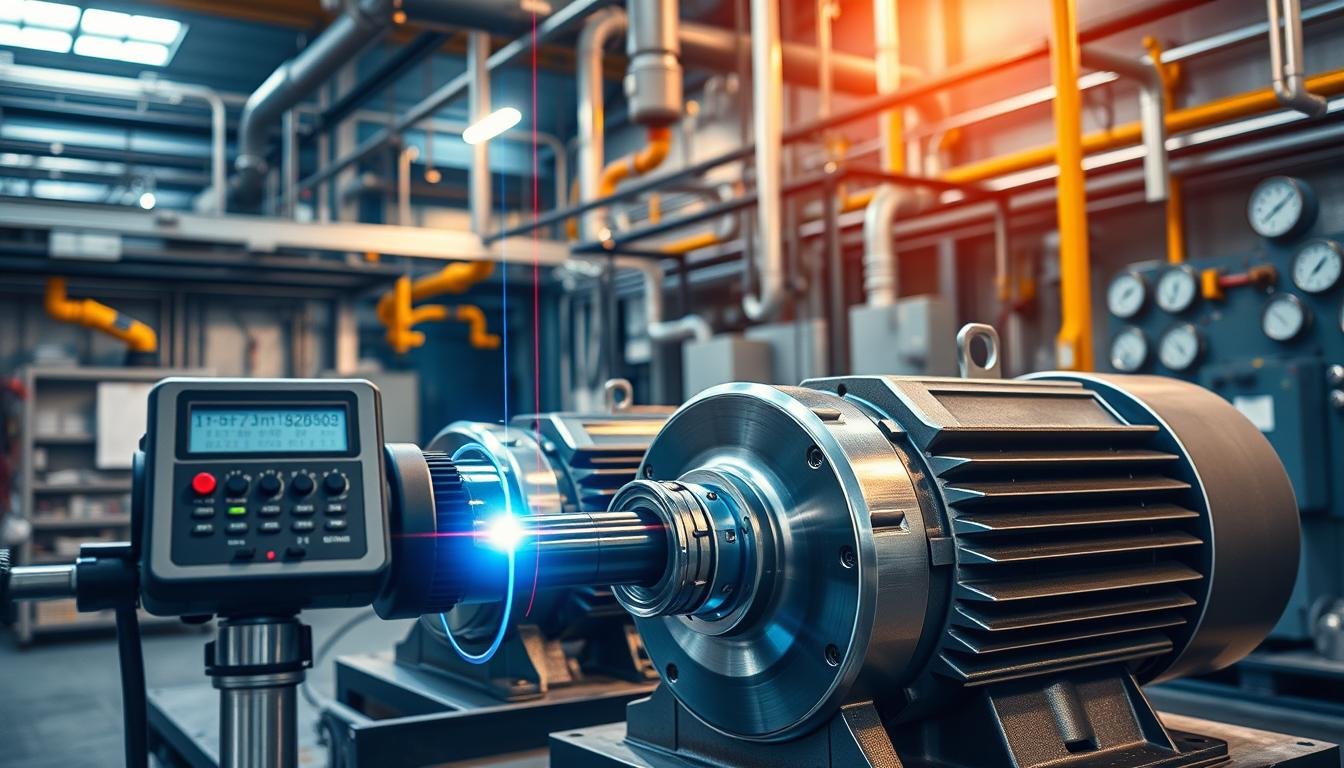

Shaft alignment methods have changed a lot, moving from old ways to new ones. Dial indicators and laser alignment systems are key to getting things right. Dial indicators are good for measuring misalignment and are easy to use.

But laser alignment technology is even better. It’s more accurate and fast. This means less time lost and better equipment life. Choosing the right tools is important for good performance.

Benefits of Proper Shaft Alignment:

Proper shaft alignment brings many benefits for machinery performance. One big plus is longer equipment life. Accurate alignment cuts down on wear and tear, making pumps and motors last longer. This means fewer replacements and repairs, saving money in the long run.

Another advantage is better energy use. Misaligned machinery uses more power, raising energy costs. Proper alignment cuts down energy use, helping the environment and saving money.

Alignment also means less downtime. When machinery runs smoothly, maintenance is less often needed. This keeps production on track and boosts productivity. Plus, well-aligned equipment costs less to maintain, saving money over time.

Alignment offers more than just immediate benefits. Regular checks and adjustments keep operations smooth and prevent big failures. This approach builds a culture of reliability and high performance in any facility.

Shaft Alignment Best Practices:

Effective shaft alignment is key to better performance and longer life of rotating equipment. A regular maintenance schedule that includes shaft alignment checks is essential. These checks help spot problems early, avoiding expensive repairs and downtime.

Using an alignment checklist is a smart move. It makes sure all important steps are followed. I suggest creating a checklist based on the Reliability Centered Maintenance framework. It should include checks for mounting conditions, signs of wear, and tool calibration.

Having trained staff for alignment tasks is also vital. I plan to attend workshops by alignment equipment makers to improve my skills. This will help keep my operations reliable and efficient.