- In today’s energy landscape, the demand for efficient, reliable, and environmentally responsible power generation has never been greater. Combined Cycle Gas Turbines (CCGTs) have emerged as a cornerstone technology in meeting these challenges. By cleverly integrating two power generation cycles, these systems extract maximum energy from fuel while minimizing environmental impact. Let’s explore how this innovative technology is transforming the power generation industry.

How Combined Cycle Gas Turbines Work:

At its core, a Combined Cycle Gas Turbine system harnesses the power of thermodynamic synergy. Think of it as getting two power plants for the price of one, with the second plant running on the waste heat from the first.

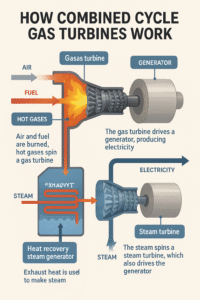

Diagram of a Combined Cycle Gas Turbine showing the integration of gas and steam cycles

The Two-Cycle Advantage:

CCGTs combine two thermodynamic cycles that work in harmony:

1). Brayton Cycle (Gas Turbine):

- The process begins with the gas turbine. Air is compressed and mixed with natural gas in the combustion chamber. When ignited, the resulting hot gases expand rapidly through the turbine blades, spinning the turbine and generating electricity through the connected generator.

- But here’s where the magic happens – unlike conventional power plants that release hot exhaust gases into the atmosphere, CCGTs capture this valuable thermal energy.

2). Rankine Cycle (Steam Turbine):

- The still-hot exhaust gases (typically around 600°C) from the gas turbine are directed to a Heat Recovery Steam Generator (HRSG). This sophisticated heat exchanger uses the exhaust heat to convert water into high-pressure steam.

- This steam then drives a second turbine connected to another generator, producing additional electricity without requiring any extra fuel. After passing through the steam turbine, the steam is condensed back to water and recycled through the system.

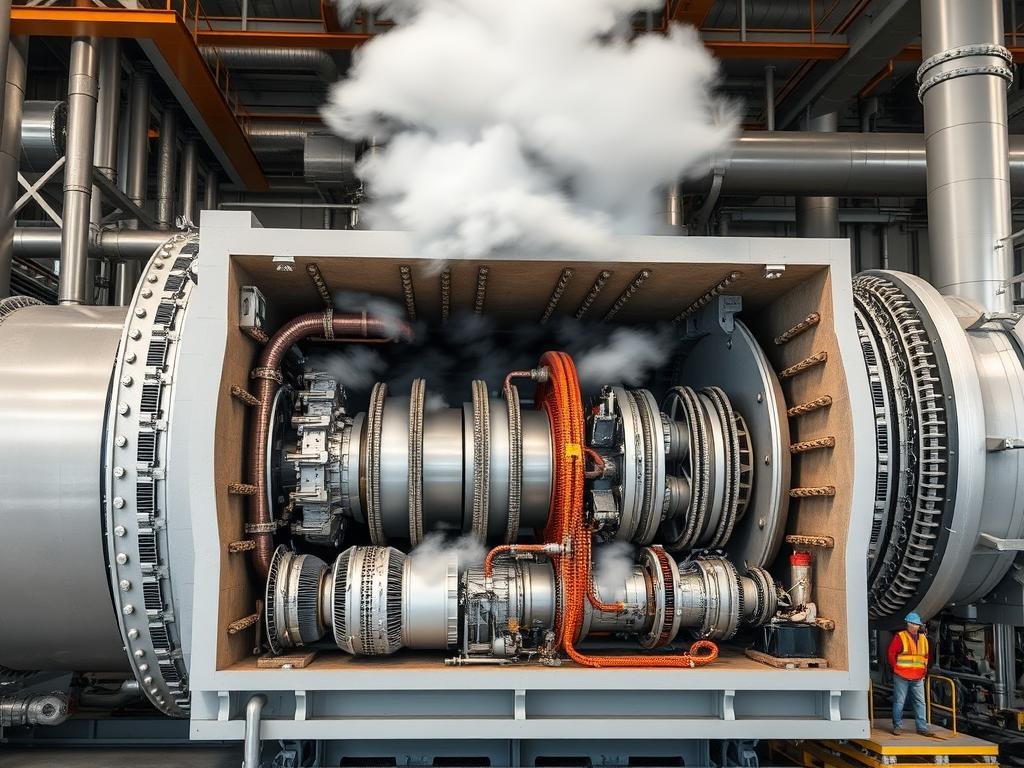

Heat Recovery Steam Generator – the critical component that captures waste heat

Benefits of Combined Cycle Gas Turbines:

The integration of gas and steam cycles creates numerous advantages that have made CCGTs increasingly popular in modern power generation.

Key Advantages of CCGTs:

- Superior Efficiency: Modern CCGTs achieve thermal efficiencies of 50-64%, significantly higher than conventional single-cycle plants (30-40%).

- Lower Emissions: Higher efficiency means less fuel burned per unit of electricity, resulting in reduced CO2, NOx, and other emissions.

- Operational Flexibility: CCGTs can start up quickly and adjust output rapidly, making them ideal for balancing variable renewable energy sources.

- Reduced Water Usage: Compared to traditional steam plants, CCGTs require less cooling water per megawatt of electricity produced.

- Cost-Effective Generation: The combination of high efficiency and relatively low capital costs results in competitive electricity production costs.

Efficiency comparison between CCGTs and other power generation technologies

Maximize Your Power Plant Efficiency:

- Discover how implementing Combined Cycle Gas Turbine technology can increase your facility’s efficiency by up to 60% while reducing emissions and operational costs.

Real-World Applications of CCGTs:

- Combined Cycle Gas Turbines have found widespread application across various sectors due to their efficiency and flexibility.

1). Utility-Scale Power Generation:

- CCGTs form the backbone of many national power grids, providing both baseload and peaking power. Their ability to ramp up quickly makes them ideal for complementing intermittent renewable energy sources like wind and solar.

2). Industrial Cogeneration:

- Many industrial facilities use CCGTs for combined heat and power (CHP) applications, where both electricity and process steam are utilized, pushing overall energy utilization to over 80%.

3). District Energy Systems:

- Urban areas benefit from CCGT plants that provide both electricity and thermal energy for heating and cooling buildings through district energy networks.

Configuration Options:

1). Single-Shaft Configuration:

- In this design, the gas turbine, steam turbine, and generator are all aligned on a single shaft. This configuration offers cost savings of 3-5%, higher efficiency, and a smaller footprint due to fewer mechanical connections and simplified systems.

2). Multi-Shaft Configuration:

- This arrangement uses separate generators for each turbine, offering greater flexibility in operation and maintenance. Multi-shaft configurations are often chosen when the gas turbine needs to operate before the combined cycle development is complete.

Modern CCGT power plant providing efficient electricity to the grid

| Parameter | Single-Shaft CCGT | Multi-Shaft CCGT |

| Capital Cost | Lower (3-5% savings) | Higher |

| Footprint | Smaller | Larger |

| Operational Flexibility | Good | Excellent |

| Maintenance Complexity | Lower | Higher |

Case Study: Efficiency in Action:

“After implementing our CCGT system, we achieved a 58% thermal efficiency rating, reduced our CO2 emissions by 40% compared to our previous coal plant, and decreased our operational costs by 25%.”

Implementation Considerations:

- While Combined Cycle Gas Turbines offer significant advantages, implementing them requires careful planning and consideration of several factors:

1). Technical Considerations:

- Site Requirements: CCGT plants need adequate space, water resources for cooling, and access to natural gas infrastructure.

- Grid Integration: The electrical system must be designed to accommodate the plant’s output and operational characteristics.

- Maintenance Planning: Regular maintenance is essential to maintain efficiency and reliability.

2). Economic Factors:

- Capital Investment: While less expensive than many alternatives, CCGTs still require significant upfront investment.

- Fuel Price Exposure: Profitability is tied to natural gas prices, which can fluctuate.

- Carbon Pricing: Future carbon regulations may impact the economics of gas-fired generation.

Expert Tip: When planning a CCGT project, consider future flexibility needs. Designing for potential hydrogen co-firing or carbon capture retrofits can extend the plant’s viable lifespan as emissions regulations tighten.

Future Trends in CCGT Technology:

The evolution of Combined Cycle Gas Turbine technology continues, with several exciting developments on the horizon:

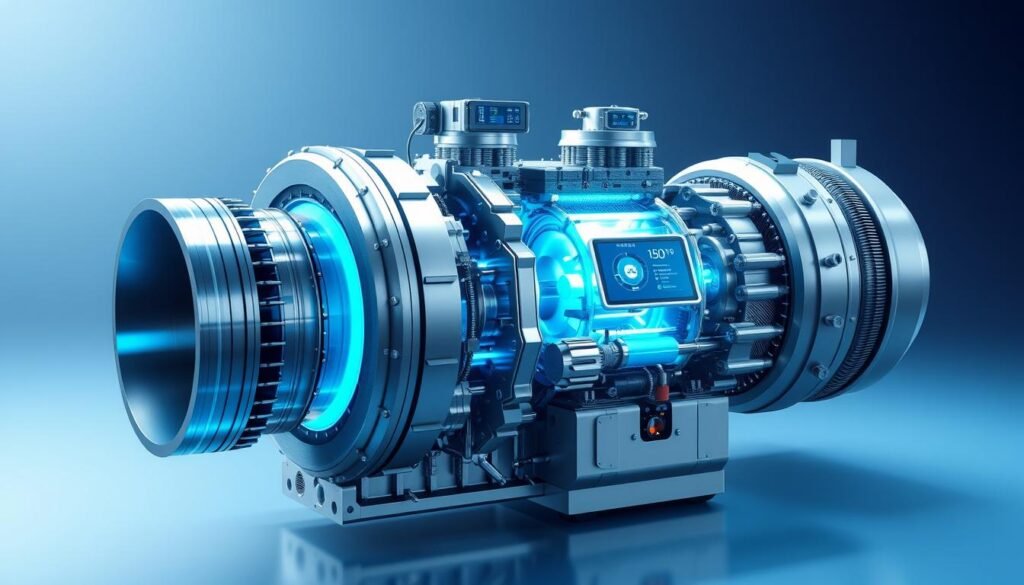

1). Hydrogen Compatibility:

- Manufacturers are developing turbines capable of running on hydrogen-natural gas blends or even 100% hydrogen, creating a pathway to zero-carbon operation of CCGT plants.

2). Advanced Materials:

- New high-temperature materials allow turbines to operate at higher temperatures, pushing efficiency beyond 65% while maintaining component durability.

3). Digital Optimization:

- AI and machine learning algorithms are being deployed to optimize combustion, predict maintenance needs, and maximize efficiency across varying operating conditions.

Next-generation CCGT technology with hydrogen capability and digital optimization

Conclusion: The Role of CCGTs in the Energy Transition:

- Combined Cycle Gas Turbines represent a critical bridge technology in the ongoing energy transition. Their high efficiency, operational flexibility, and lower emissions compared to coal make them valuable assets as we work toward a more sustainable energy future.

- While renewable energy sources continue to grow, CCGTs provide the reliable, dispatchable power needed to maintain grid stability. And with innovations like hydrogen compatibility, these systems have the potential to remain relevant even in a carbon-neutral energy landscape.

- For energy providers, industrial facilities, and utilities seeking to balance efficiency, reliability, and environmental responsibility, Combined Cycle Gas Turbines offer a proven solution that continues to evolve with our changing energy needs.

Frequently Asked Questions:

1). What is the typical efficiency of a Combined Cycle Gas Turbine plant?

- Modern CCGT plants typically achieve thermal efficiencies between 50% and 64%, with the most advanced designs pushing toward the upper end of this range. This is significantly higher than conventional single-cycle power plants, which typically range from 30% to 40% efficiency.

2). How do Combined Cycle Gas Turbines compare to renewable energy sources?

- While renewable sources like wind and solar have zero fuel costs and emissions during operation, they are intermittent. CCGTs complement renewables by providing dispatchable power that can ramp up quickly when renewable output drops. The combination of renewables and flexible CCGT capacity creates a more reliable and resilient power system.

3). What fuels can be used in Combined Cycle Gas Turbines?

- While natural gas is the most common fuel, modern CCGTs can also operate on a variety of other fuels including hydrogen blends, biogas, syngas, and light distillate oils. Many manufacturers are developing turbines capable of running on increasing percentages of hydrogen, potentially enabling zero-carbon operation in the future.