Fundamental Working Principles of Steam Turbines

The operation of a steam turbine is governed by fundamental thermodynamic principles, primarily following the Rankine cycle, which describes the conversion of heat into mechanical work. This process begins when high-pressure, high-temperature steam enters the turbine through stationary nozzles or guide vanes. These nozzles accelerate the steam by converting its pressure energy into kinetic energy, directing high-velocity steam jets onto the turbine’s rotating blades. As steam flows through the turbine, it expands and cools, transferring its energy to the blades and causing the rotor to spin. This rotational energy can then be harnessed to drive generators for electricity production or to power mechanical equipment such as pumps, compressors, or ship propellers. The expanded, low-pressure steam exits the turbine and typically flows to a condenser, where it returns to liquid form before being pumped back to the boiler to repeat the cycle. This continuous process enables the efficient extraction of energy from steam, with modern turbines achieving thermal efficiencies of up to 45% in conventional applications and even higher in combined cycle configurations.

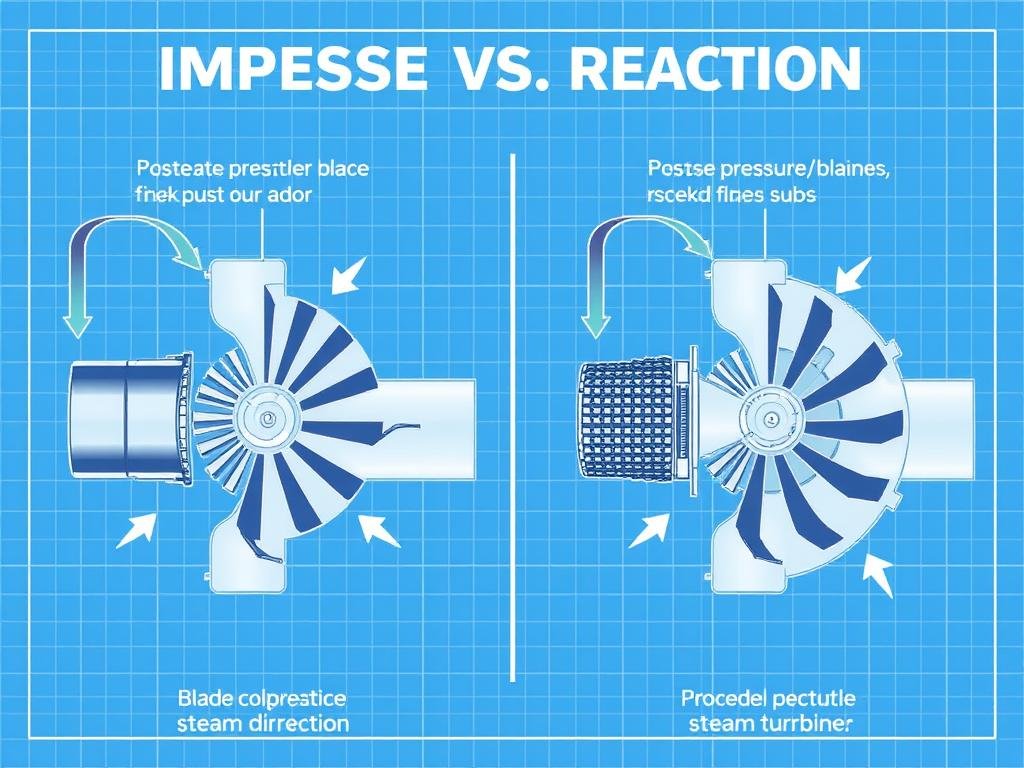

Steam turbines operate on two fundamental principles: impulse and reaction. In impulse turbines, steam is accelerated through fixed nozzles and directed at the turbine blades, where the kinetic energy of the steam creates an impulse force as it strikes the blades and changes direction. The pressure remains constant as steam passes through the moving blades, with energy transfer occurring solely through velocity changes. Conversely, reaction turbines extract energy as steam passes through specially shaped passages formed by both stationary and moving blades. As steam flows through these converging passages, it expands and accelerates, creating a reaction force that propels the blades forward. In practice, most modern steam turbines incorporate elements of both impulse and reaction principles, with impulse stages typically used in the high-pressure sections where steam enters the turbine and reaction stages employed in the lower-pressure sections. This hybrid approach optimizes energy extraction across the wide pressure range that steam undergoes from inlet to exhaust, maximizing overall turbine efficiency while accommodating the mechanical and thermal stresses that occur throughout the turbine.

The concept of staging represents another crucial aspect of steam turbine design. Rather than expanding steam in a single step, which would require impractically large blade velocities to efficiently capture the energy, turbines employ multiple stages to gradually extract energy as steam expands. Each stage consists of a set of stationary blades (nozzles or stators) followed by a row of moving blades (rotors). This arrangement allows for controlled expansion of steam across numerous pressure drops, enabling more efficient energy conversion while maintaining practical rotor speeds. Modern large power generation turbines may contain dozens of stages arranged in high-pressure, intermediate-pressure, and low-pressure sections, often housed in separate casings. The high-pressure section handles the initial expansion of steam at temperatures that can exceed 600°C (1,112°F) and pressures above 300 bar (4,350 psi) in supercritical applications. The intermediate and low-pressure sections continue the expansion process, with the final stages operating under vacuum conditions created by the condenser. This multi-stage design, combined with precise blade profiling and advanced materials, allows modern steam turbines to achieve remarkable efficiency while handling enormous power outputs that can exceed 1,500 MW in the largest units.

Types of Steam Turbines and Their Applications

Figure 2: Comparison of impulse (left) and reaction (right) turbine blade designs showing different steam flow patterns

Classification by Operating Principle

Steam turbines are primarily classified according to their operating principles, with the two fundamental categories being impulse and reaction turbines. Impulse turbines, exemplified by the de Laval and Curtis designs, feature nozzles that accelerate steam to high velocities before it strikes the rotor blades. The kinetic energy of the steam jet creates an impulse force on the blade, causing rotation, while the steam pressure remains relatively constant across the moving blades. These turbines excel in applications requiring high power density and are particularly effective when operating with high-pressure steam. The Curtis stage, a variation of the impulse design, uses multiple rows of moving blades alternating with fixed blades to extract more energy from the steam velocity. Reaction turbines, typified by the Parsons design, operate on a different principle where steam continuously expands as it passes through both stationary and moving blade passages. The acceleration and pressure drop across the moving blades create a reaction force that drives the rotor. Reaction turbines generally achieve higher efficiency than pure impulse designs but require more precise clearances and sealing to prevent steam leakage. Most modern large steam turbines employ a hybrid approach, using impulse stages in the high-pressure sections where steam first enters and reaction stages in the intermediate and low-pressure sections, combining the advantages of both principles to optimize overall performance across the wide range of pressures and temperatures encountered from inlet to exhaust.

Classification by Steam Flow and Construction

Beyond the basic operating principles, steam turbines are further categorized based on their steam flow configuration and construction characteristics. Axial flow turbines, the most common type, feature steam flowing parallel to the axis of rotation, passing through alternating rows of stationary and rotating blades. Radial flow turbines, less common in modern applications, direct steam perpendicular to the axis of rotation. In terms of casing arrangement, single-casing turbines house all stages within one pressure vessel, offering simplicity and cost-effectiveness for smaller applications. Tandem-compound turbines utilize multiple casings (typically high-pressure, intermediate-pressure, and low-pressure) connected in series on a single shaft or on separate shafts coupled together, allowing for reheat cycles and more efficient expansion across wide pressure ranges. Cross-compound configurations employ two separate turbine-generator sets operating at different speeds, optimized for their respective pressure ranges and connected to the same steam cycle. Double-flow designs split the steam path symmetrically within a casing, with steam entering in the middle and flowing in opposite directions toward both ends, balancing axial thrust forces and enabling higher mass flow rates. Extraction turbines feature controlled openings along the casing where steam can be withdrawn at intermediate pressures for industrial processes or feedwater heating, enhancing overall plant efficiency. Induction turbines allow for additional steam to be admitted at intermediate stages, providing flexibility for variable process steam conditions. Each of these configurations offers specific advantages for particular applications, allowing steam turbine technology to be optimized for diverse industrial and power generation requirements.

Optimize Your Turbine Selection Process

Access our comprehensive steam turbine selection guide with detailed specifications, performance curves, and application-specific recommendations to identify the optimal turbine configuration for your requirements.

Classification by Application and Size

Steam turbines span an extraordinary range of sizes and applications, from massive utility units exceeding 1,500 MW to compact industrial turbines of just a few kilowatts. Utility steam turbines, designed primarily for electricity generation in large power plants, prioritize maximum thermal efficiency and typically operate at constant speed to maintain grid frequency. These behemoths can weigh thousands of tons and stretch over 30 meters in length, incorporating dozens of precisely engineered blade rows to extract maximum energy from the steam. Industrial steam turbines, by contrast, are designed for diverse applications including mechanical drives for compressors, pumps, and process equipment, as well as combined heat and power systems. These units emphasize reliability, operational flexibility, and quick start-up capabilities rather than absolute efficiency. Mechanical drive turbines directly power rotating equipment without the intermediate step of electricity generation, offering simplicity and efficiency for applications like pipeline compressors or refinery pumps. Condensing turbines exhaust steam at sub-atmospheric pressures to a condenser, maximizing energy extraction for electricity generation. Non-condensing or back-pressure turbines exhaust steam at pressures above atmospheric for process heating applications, exemplifying the cogeneration approach that provides both mechanical power and useful heat. Marine propulsion turbines, though less common today than in the mid-20th century, are specialized for shipboard use with compact designs, high power density, and reversing capability. The remarkable versatility of steam turbine technology allows it to be scaled and adapted across this vast spectrum of applications, with each design carefully optimized for its specific operating conditions, performance requirements, and economic constraints.

Efficiency Factors and Performance Optimization

Thermodynamic Efficiency Considerations

The thermodynamic efficiency of steam turbines represents a critical performance metric that directly impacts fuel consumption, operating costs, and environmental footprint. At its core, steam turbine efficiency is governed by the Second Law of Thermodynamics and the limitations of the Rankine cycle, which describes the ideal thermodynamic process for converting heat into mechanical work using steam. The theoretical maximum efficiency of this cycle is determined by the temperature difference between the steam at inlet and exhaust conditions, following the Carnot efficiency principle that higher temperature differentials yield greater potential efficiency. In practice, actual turbine efficiency falls below this theoretical maximum due to various irreversible losses. Isentropic efficiency, a key performance indicator, compares the actual work output to the ideal work that would be produced by an isentropic (constant entropy) expansion process. Modern large steam turbines achieve isentropic efficiencies of 85-90% in optimal conditions, representing remarkable engineering achievement given the complex fluid dynamics involved. Enhancing thermodynamic efficiency involves several strategies: increasing initial steam temperature and pressure (with supercritical and ultra-supercritical steam conditions now exceeding 600°C and 300 bar), implementing steam reheat cycles where partially expanded steam is returned to the boiler for reheating before further expansion, employing regenerative feedwater heating where steam is extracted at various turbine stages to preheat boiler feedwater, and optimizing the condenser vacuum to lower the exhaust temperature. Each percentage point improvement in turbine efficiency translates to substantial fuel savings and emissions reductions over the multi-decade operational life of these machines, driving continuous innovation in materials, design, and operational practices.

Figure 3: Rankine cycle diagram showing key components and efficiency factors in steam turbine power generation

Mechanical and Aerodynamic Efficiency Factors

Beyond thermodynamic considerations, the mechanical and aerodynamic design of steam turbines significantly impacts their overall efficiency and reliability. Blade design represents perhaps the most critical aspect of turbine aerodynamic efficiency, with modern computational fluid dynamics enabling sophisticated three-dimensional profiling that minimizes flow separation, secondary flows, and shock losses. Blade tip clearances must be precisely controlled, as excessive gaps between rotating blades and the stationary casing allow steam to bypass the blades without performing useful work, while insufficient clearance risks catastrophic blade rubs during thermal expansion or shaft deflection. Sealing systems, including labyrinth seals, brush seals, and advanced abradable coatings, minimize internal leakage paths that would otherwise allow steam to bypass stages and reduce efficiency. Bearing design affects mechanical efficiency through friction losses and oil churning, with modern tilting-pad journal bearings and thrust bearings optimized to minimize these parasitic losses while maintaining rotor stability across the operating range. Windage losses occur as the rotating components churn the steam atmosphere within the casing, particularly in low-pressure sections where the specific volume of steam is high; these are mitigated through careful aerodynamic design of the rotating elements. Moisture losses become significant in the final low-pressure stages where steam begins to condense, with water droplets causing erosion damage and efficiency reduction; moisture removal systems and specialized blade designs help address this challenge. Balance of plant considerations, including steam path cleanliness, condenser performance, and extraction optimization, further influence overall cycle efficiency. The cumulative effect of these mechanical and aerodynamic optimizations can represent several percentage points of efficiency—a significant impact when considering that each percentage point in a large utility turbine can represent millions of dollars in fuel savings over its operational lifetime.

Material Selection and Advanced Technologies

Material selection plays a pivotal role in steam turbine efficiency and reliability, particularly as the industry pushes toward higher temperatures and pressures to improve thermodynamic performance. High-temperature components in modern advanced turbines utilize specialized nickel-based superalloys and ferritic-martensitic steels with precise alloying elements that provide the necessary creep resistance, fatigue strength, and oxidation resistance required for sustained operation under extreme conditions. These materials enable inlet steam temperatures exceeding 600°C in ultra-supercritical applications, significantly enhancing cycle efficiency. Blade materials have evolved from simple stainless steels to sophisticated precipitation-hardened alloys with directionally solidified or single-crystal structures in the most demanding applications, allowing for thinner, more aerodynamically optimized profiles while maintaining mechanical integrity. Protective coatings, including thermal barrier coatings and oxidation-resistant overlays, further extend component life and maintain performance by preventing degradation mechanisms that would otherwise compromise efficiency over time. Advanced manufacturing technologies, such as additive manufacturing and precision machining, enable complex geometries that were previously impossible to produce, allowing for integrated cooling passages, optimized flow paths, and reduced part counts. Digital technologies have revolutionized both design and operation, with computational fluid dynamics enabling virtual prototyping and optimization of complex three-dimensional flow paths, while digital twins and advanced monitoring systems provide real-time performance optimization during operation. Variable geometry features, including adjustable guide vanes and controllable extraction systems, allow turbines to maintain high efficiency across varying load conditions—an increasingly important capability as power grids incorporate more intermittent renewable generation. Together, these material and technological advancements continue to push the efficiency boundaries of steam turbine technology while extending service life and reducing maintenance requirements.

Maximize Your Turbine Efficiency

Our team of specialized engineers can analyze your existing steam turbine installation and identify optimization opportunities to improve efficiency, reduce operational costs, and extend equipment life.

Industrial and Power Generation Applications

Utility Power Generation

Steam turbines form the cornerstone of utility-scale power generation worldwide, converting thermal energy from various heat sources into electricity with unmatched reliability and scale. In conventional fossil fuel power plants, steam turbines transform the heat energy released from coal, natural gas, or oil combustion into rotational mechanical energy that drives electrical generators. These installations typically employ large condensing turbines arranged in high-pressure, intermediate-pressure, and low-pressure sections to maximize energy extraction as steam expands from initial conditions that can exceed 600°C and 300 bar to final condensing conditions under vacuum. Nuclear power plants similarly rely on steam turbines, though with somewhat lower steam parameters due to the temperature limitations of nuclear reactor materials. Despite these lower steam conditions, nuclear turbines are among the largest in the world, with single units exceeding 1,500 MW in capacity. The modularity of steam turbine technology allows for various cycle configurations to enhance efficiency, including supercritical and ultra-supercritical cycles that operate above the critical point of water (374°C, 221 bar), reheat cycles that return partially expanded steam to the boiler for additional heating, and regenerative cycles that use steam extraction for feedwater heating. Combined cycle power plants pair gas turbines with heat recovery steam generators and steam turbines to achieve overall efficiencies exceeding 60%—significantly higher than either technology could achieve independently. Concentrated solar power plants use mirrors to focus solar energy, generating high-temperature heat that produces steam for conventional turbine-driven generation. Geothermal power plants harness naturally occurring steam or hot water from underground reservoirs to drive specially designed steam turbines adapted for the unique chemical composition and lower temperature conditions of geothermal resources. Across these diverse applications, steam turbines demonstrate remarkable versatility in converting thermal energy to electricity at scales ranging from a few megawatts to over 1,500 MW per unit.

Industrial Process Applications

Beyond utility power generation, steam turbines serve critical roles across diverse industrial sectors, where their ability to efficiently convert steam energy into mechanical power addresses numerous process requirements. In petroleum refineries and petrochemical plants, steam turbines drive critical equipment including large compressors for processes like catalytic cracking, hydrotreating, and refrigeration systems. These applications often utilize extraction or induction turbines that can accommodate varying process steam conditions while providing reliable mechanical power. The pulp and paper industry employs back-pressure and extraction turbines in cogeneration systems that simultaneously generate electricity and provide process steam for paper drying, digester operation, and other thermal processes—often using biomass residuals from the papermaking process as fuel. Chemical manufacturing facilities utilize steam turbines for driving synthesis gas compressors in ammonia and methanol production, as well as for generating electricity from process steam that would otherwise be throttled to lower pressures. Steel mills and metal processing plants employ steam turbines to recover energy from blast furnace gas and coke oven gas, converting these byproduct fuels into valuable mechanical and electrical power. Desalination plants, particularly those using multi-stage flash or multiple-effect distillation technologies, incorporate steam turbines in their thermal processes, sometimes in innovative configurations that combine power generation with water production. Food processing facilities utilize steam turbines in cogeneration systems that provide both electricity and process steam for cooking, sterilization, and drying operations. Across these industrial applications, steam turbines offer several advantages: they can handle a wide range of steam conditions, provide extremely reliable operation with minimal maintenance, offer excellent part-load efficiency compared to alternatives, and can be precisely matched to process requirements through careful sizing and design. The ability to extract or admit steam at intermediate pressures makes industrial steam turbines particularly valuable in complex processes with multiple steam headers operating at different pressure levels.

Marine and Specialized Applications

Steam turbines have played a transformative role in marine propulsion since their introduction in the late 19th century, revolutionizing naval warfare and commercial shipping through their superior power density, reliability, and reduced vibration compared to reciprocating steam engines. Though less common in modern vessels due to competition from diesel engines and gas turbines, steam turbines remain the propulsion system of choice for nuclear-powered warships and submarines, where their quiet operation, reliability, and ability to handle the high power output from nuclear reactors provide significant advantages. Large liquefied natural gas (LNG) carriers often employ steam turbines that can utilize boil-off gas from their cargo as fuel, offering both economic and safety benefits by consuming gas that would otherwise require re-liquefaction or disposal. Beyond marine applications, steam turbines serve in specialized roles across various industries. In district heating systems, extraction and back-pressure turbines generate electricity while providing controlled steam extraction for community heating networks, maximizing overall energy utilization. Waste-to-energy facilities employ steam turbines to convert municipal solid waste into electricity through steam generated in waste combustion boilers. Biomass power plants similarly use steam turbines to generate renewable electricity from agricultural residues, forestry byproducts, and dedicated energy crops. Compressed air energy storage systems sometimes incorporate steam turbines in innovative configurations that enhance overall system efficiency. Mobile power plants mounted on barges or ships, known as powerships, frequently utilize steam turbines for their reliability and power density, providing electricity to regions with underdeveloped infrastructure. Pumped storage hydroelectric facilities occasionally employ steam turbines as mechanical drives for the pumping phase of their operation. These diverse applications demonstrate the remarkable versatility of steam turbine technology, which continues to find new uses even after more than a century of development and refinement.

Figure 4: Large industrial steam turbine installation showing scale and integration with power plant systems

Maintenance Practices and Reliability Considerations

Preventive Maintenance Strategies

Effective preventive maintenance forms the cornerstone of steam turbine reliability, protecting these substantial capital investments and preventing costly forced outages. Comprehensive maintenance programs begin with regular condition monitoring, including vibration analysis to detect incipient mechanical issues, performance testing to identify efficiency degradation, and oil analysis to assess lubricant condition and detect potential bearing wear. Thermographic inspections help identify hot spots that might indicate steam leaks or insulation failures, while ultrasonic testing can detect cracks or material degradation in critical components. Scheduled inspections follow carefully developed protocols with varying levels of invasiveness: routine inspections conducted during normal operation, minor inspections requiring brief outages to access specific components, and major overhauls involving complete disassembly of the turbine to inspect all internal components. These major overhauls typically occur at intervals of 5-10 years depending on the turbine type, operating conditions, and manufacturer recommendations. During these comprehensive inspections, technicians examine blade profiles for erosion, deposits, or cracking; check clearances between rotating and stationary components; inspect seals for wear; examine bearings for damage; and verify the integrity of the rotor, diaphragms, and casing. Advanced non-destructive testing techniques, including dye penetrant testing, magnetic particle inspection, ultrasonic testing, and eddy current analysis, help detect surface and subsurface flaws that could develop into failures. Borescope inspections using fiber optic technology allow visual examination of internal components without complete disassembly in some cases. Valve testing and servicing ensure proper operation of critical control, stop, and bypass valves that protect the turbine from overspeed and other dangerous conditions. Instrumentation calibration maintains the accuracy of the monitoring systems that operators rely on for safe turbine operation. Together, these preventive maintenance activities help identify and address potential issues before they develop into failures, maximizing availability while minimizing the risk of catastrophic damage.

Common Failure Modes and Mitigation

Understanding common failure modes enables more effective maintenance planning and design improvements for steam turbines. Blade failures represent one of the most serious potential issues, with several underlying mechanisms: high-cycle fatigue caused by resonant vibration when blade natural frequencies align with excitation forces; low-cycle fatigue from thermal cycling during startups and shutdowns; stress corrosion cracking particularly in wet steam environments; erosion from water droplets in low-pressure stages or solid particles in the steam path; and foreign object damage from broken components or external contaminants. Mitigation strategies include advanced blade designs with integral damping features, careful material selection, protective coatings, moisture removal systems, and comprehensive steam quality management. Bearing failures typically result from lubrication issues, misalignment, excessive loading, or contamination; these are addressed through oil conditioning systems, precise alignment procedures, vibration monitoring, and proper startup protocols. Rotor issues include thermal bowing from uneven heating or cooling, which can cause dangerous vibration; this is mitigated through controlled heating procedures, turning gear operation during shutdowns, and proper warm-up sequences. Seal degradation leads to efficiency losses and potential damage from steam impingement; modern designs employ advanced materials and configurations to extend seal life. Control system failures can result in dangerous overspeed conditions or improper operation; redundant systems, regular testing, and modernization programs help maintain reliable control. Casing and joint leakage reduces efficiency and can create safety hazards; proper gasket selection, controlled bolt tensioning, and thermal expansion accommodation in the design address these concerns. Steam path deposits from contaminants in the steam reduce efficiency and can cause imbalance; water chemistry control and periodic chemical cleaning help maintain clean steam paths. Stress corrosion cracking in rotors and discs, particularly in the high-stress, high-temperature environments of the first stages, requires careful material selection and regular inspection. By understanding these failure mechanisms and implementing appropriate preventive measures, operators can significantly extend turbine life while maintaining safety and performance.

Enhance Your Maintenance Program

Download our comprehensive steam turbine maintenance guide with detailed inspection checklists, troubleshooting procedures, and best practices developed from decades of field experience.

Modern Monitoring and Diagnostic Techniques

The evolution of monitoring and diagnostic technologies has transformed steam turbine maintenance from a largely time-based approach to a more sophisticated condition-based strategy that optimizes maintenance activities while enhancing reliability. Online monitoring systems continuously collect data on critical parameters including vibration signatures, bearing temperatures, differential expansion, shaft position, steam conditions, valve positions, and performance indicators. Advanced vibration analysis techniques go beyond simple amplitude measurements to include orbit analysis, spectral analysis, and transient analysis that can identify specific mechanical issues such as misalignment, unbalance, bearing wear, or blade resonance. Acoustic emission monitoring detects high-frequency stress waves generated by developing cracks or other defects, potentially identifying issues earlier than conventional vibration analysis. Thermodynamic performance monitoring tracks efficiency parameters and heat rate, identifying degradation that might indicate steam path fouling, seal leakage, or other issues affecting performance. Oil debris monitoring systems use various technologies to detect and characterize wear particles in lubricating oil, providing early indication of bearing or journal wear before significant damage occurs. Partial discharge monitoring for generators connected to steam turbines helps assess insulation condition without requiring disassembly. The integration of these monitoring systems with plant control and data systems has enabled the development of digital twins—virtual models of specific turbines that simulate their behavior under various conditions and predict future performance based on current operating data. Machine learning algorithms increasingly analyze the vast quantities of data generated by these monitoring systems, identifying subtle patterns that might indicate developing problems before they would be apparent to human operators. Remote monitoring centers staffed by specialists can provide expert analysis and recommendations for multiple plants, leveraging specialized expertise more effectively. Together, these advanced monitoring and diagnostic capabilities enable more precise maintenance planning, reduce unnecessary outages, and help prevent unexpected failures—ultimately extending equipment life while reducing lifetime maintenance costs and improving overall reliability.

Future Developments and Technological Trends

Advanced Materials and Manufacturing

The future of steam turbine technology is being shaped by revolutionary advances in materials science and manufacturing techniques that promise to overcome current limitations in temperature, pressure, and component life. Nickel-based superalloys with enhanced high-temperature capabilities continue to evolve, with sophisticated alloying elements and microstructural control enabling operation at ever-higher temperatures without sacrificing creep resistance or corrosion protection. Single-crystal blade manufacturing, already established in gas turbines, is finding increased application in the most demanding steam turbine components, eliminating grain boundaries that represent weak points under high-temperature stress conditions. Advanced ferritic-martensitic steels with carefully controlled precipitate structures provide improved creep resistance for rotors and casings while maintaining the favorable thermal expansion characteristics needed for large components. Ceramic matrix composites, though still primarily in the research phase for steam applications, offer potential for components that can withstand extreme temperatures beyond the capabilities of metallic alloys. Thermal barrier coatings with enhanced durability and reduced thermal conductivity allow metal components to operate at higher steam temperatures by providing thermal insulation while protecting against oxidation. Additive manufacturing (3D printing) technologies are transforming the production of complex components, enabling integrated cooling passages, optimized internal structures, and geometries that would be impossible to produce with conventional manufacturing methods. This technology also offers potential for rapid prototyping, spare parts production, and repairs that extend component life. Hybrid manufacturing approaches combine additive techniques with conventional machining to leverage the advantages of both methods. Advanced joining technologies, including friction welding, diffusion bonding, and specialized brazing techniques, enable the creation of components with different materials optimized for specific local conditions within the turbine. Surface engineering technologies, including shot peening, laser shock peening, and specialized heat treatments, enhance fatigue resistance by introducing beneficial compressive stresses in critical areas. Together, these material and manufacturing advances are enabling the next generation of steam turbines with higher efficiency, greater operational flexibility, and extended service life—continuing the evolution of this mature yet still-advancing technology.

Digitalization and Smart Technologies

The integration of digital technologies is revolutionizing steam turbine design, operation, and maintenance, creating unprecedented opportunities for performance optimization and reliability enhancement. Digital twin technology creates virtual replicas of specific turbines that simulate their behavior under various conditions, enabling operators to predict performance, test operational strategies, and identify optimal maintenance timing without risking the actual equipment. These sophisticated models incorporate design data, material properties, operating history, and real-time sensor inputs to provide increasingly accurate representations of physical assets. Advanced analytics and machine learning algorithms process the vast quantities of data generated by modern monitoring systems, identifying subtle patterns and correlations that might escape human analysis and predicting developing issues before they become serious problems. These predictive capabilities are transforming maintenance strategies from preventive to predictive approaches, optimizing maintenance timing and scope based on actual equipment condition rather than fixed intervals. Augmented reality systems support maintenance activities by overlaying digital information on physical equipment, guiding technicians through complex procedures and providing access to documentation, historical data, and remote expert assistance. Remote monitoring and operation capabilities enable centralized expertise to support multiple facilities, with specialists analyzing data from numerous turbines to identify best practices and potential issues. Automated control systems with adaptive algorithms optimize turbine operation in real-time, responding to changing grid conditions, steam parameters, and equipment status to maximize efficiency and reliability while respecting operational constraints. Cybersecurity has become an essential consideration as these digital systems become more integrated and connected, with sophisticated protection mechanisms needed to prevent unauthorized access or interference with these critical power generation assets. Edge computing architectures process critical data locally before transmission to central systems, reducing latency for time-sensitive functions and providing resilience against communication disruptions. The ongoing convergence of operational technology and information technology is creating increasingly integrated systems that optimize not just individual turbines but entire power plants and even regional energy systems, balancing multiple objectives including efficiency, emissions, flexibility, and equipment life consumption.

Sustainability and Efficiency Innovations

As global energy systems evolve toward greater sustainability, steam turbine technology continues to adapt and innovate to meet changing requirements while building on its fundamental strengths. Ultra-supercritical and advanced ultra-supercritical steam cycles push temperature and pressure boundaries to achieve higher thermodynamic efficiencies, with research programs targeting steam conditions of 700°C and beyond—requiring sophisticated materials and design approaches but offering significant efficiency improvements that directly translate to reduced emissions per unit of electricity generated. Flexible operation capabilities are becoming increasingly important as power grids incorporate larger percentages of variable renewable generation; modern steam turbines incorporate features like variable guide vanes, advanced sealing systems, and sophisticated control algorithms that enable faster startups, improved part-load efficiency, and wider operating ranges without sacrificing component life. Hybrid energy systems that integrate steam turbines with other technologies offer promising pathways for decarbonization; examples include concentrated solar power plants that use molten salt thermal storage to drive conventional steam cycles, biomass-fired or waste-to-energy plants that replace fossil fuels with renewable or recycled feedstocks, and integrated gasification combined cycle systems that can incorporate carbon capture while maintaining high efficiency. Hydrogen co-firing or pure hydrogen combustion represents another pathway for existing steam turbine infrastructure to operate with reduced or zero carbon emissions as hydrogen production becomes more economical. Thermal energy storage integration allows steam turbine power plants to decouple generation from demand, storing energy during low-demand periods and releasing it during peak demand—a capability that becomes increasingly valuable in grids with high renewable penetration. Supercritical CO₂ cycles, while technically not steam cycles, represent an evolution of turbine technology that could potentially achieve higher efficiencies than conventional steam cycles at smaller physical scales; research and demonstration projects continue to advance this technology toward commercial viability. Water conservation innovations, including advanced air-cooled condensers and water recovery systems, address the significant water consumption traditionally associated with steam cycle power generation. These diverse innovations demonstrate how steam turbine technology continues to evolve and adapt to changing energy system requirements while maintaining its central role in reliable, efficient power generation.

Conclusion: The Enduring Relevance of Steam Turbine Technology

Despite being invented over a century ago, steam turbine technology maintains its position as a cornerstone of global energy systems through continuous evolution and adaptation to changing requirements. The fundamental advantages that established steam turbines as dominant power generation technology—reliability, scalability, efficiency, and versatility—remain relevant today, even as the energy landscape transforms around them. Modern steam turbines bear little resemblance to their early predecessors, incorporating advanced materials that withstand extreme conditions, sophisticated blade designs optimized through computational fluid dynamics, precision manufacturing techniques that maintain tight tolerances, and digital control systems that optimize performance across varying conditions. This continuous technological advancement has enabled steam turbines to maintain their relevance through dramatic changes in energy markets, environmental requirements, and operational demands. Looking forward, steam turbines will continue to play vital roles in diverse applications: providing reliable baseload and flexible generation in evolving electrical grids, efficiently converting thermal energy from next-generation nuclear reactors, enabling thermal energy storage for grid stability, recovering waste heat from industrial processes, and serving as the power conversion technology for renewable thermal systems like concentrated solar power. The ongoing development of more efficient cycles, more durable materials, and more flexible operational capabilities ensures that this mature yet still-evolving technology will remain an essential component of global energy systems for decades to come, continuing to convert the expansive power of steam into the mechanical energy that drives our modern world.

It fantastic!

I got information about the steam turbine, principle, types and application.

All information is easy to understand and very good

You create a new way to learning the deep therotical information online

I found this link on WhatsApp channel

And I will read it daily in future

Thank you and I appreciate your work

Thanks for your feedback. kindly share the whatsapp and website link to your friends circle.