- Choosing the right pump for your industrial application can significantly impact efficiency, maintenance costs, and overall performance. When it comes to moving fluids, two main pump types dominate the industry: positive displacement pumps and centrifugal pumps. Each has distinct advantages and ideal applications, but understanding their differences doesn’t have to be complicated.

- In this guide, we’ll break down the key differences between these pump types in plain language, helping engineers, technicians, and industry newcomers make informed decisions for their specific needs.

Understanding the Basics: What Are These Pumps?

What Is a Centrifugal Pump?

- A centrifugal pump uses rotational energy to move fluids. Think of it like a water wheel at an old mill. The pump has a spinning impeller (like a fan) that flings fluid outward using centrifugal force, creating both velocity and pressure. As the fluid moves through the expanding chamber (called a volute), this velocity converts to pressure energy that pushes the fluid through the system.

What Is a Positive Displacement Pump?

- A positive displacement pump traps and moves a fixed amount of fluid with each cycle. Imagine squeezing toothpaste from a tube – you’re forcing a specific volume forward with each squeeze. These pumps use rotating or reciprocating components to create sealed chambers that trap fluid at the inlet and force it to the outlet, regardless of pressure conditions.

How They Work: Simple Explanations:

Centrifugal Pump Working Principle:

A centrifugal pump works much like a spinning water ride at an amusement park. When you spin a bucket of water, the water climbs up the sides due to centrifugal force. Similarly, when the impeller in a centrifugal pump spins:

- Fluid enters near the center (eye) of the impeller

- The spinning impeller throws fluid outward with centrifugal force

- This creates a low-pressure area at the center, drawing in more fluid

- The fluid gains velocity as it moves through the expanding chamber

- This velocity converts to pressure as the fluid exits

Positive Displacement Pump Working Principle:

A positive displacement pump works like a mechanical syringe. When you pull back on a syringe, it creates a vacuum that draws in liquid. When you push, it forces that exact volume out. In a positive displacement pump:

- Rotating or reciprocating parts create expanding cavities on the inlet side

- These expanding cavities create suction that draws in fluid

- The cavities then seal and move toward the discharge side

- As the cavities shrink, they force the trapped fluid out

- Each cycle moves a fixed volume, regardless of pressure

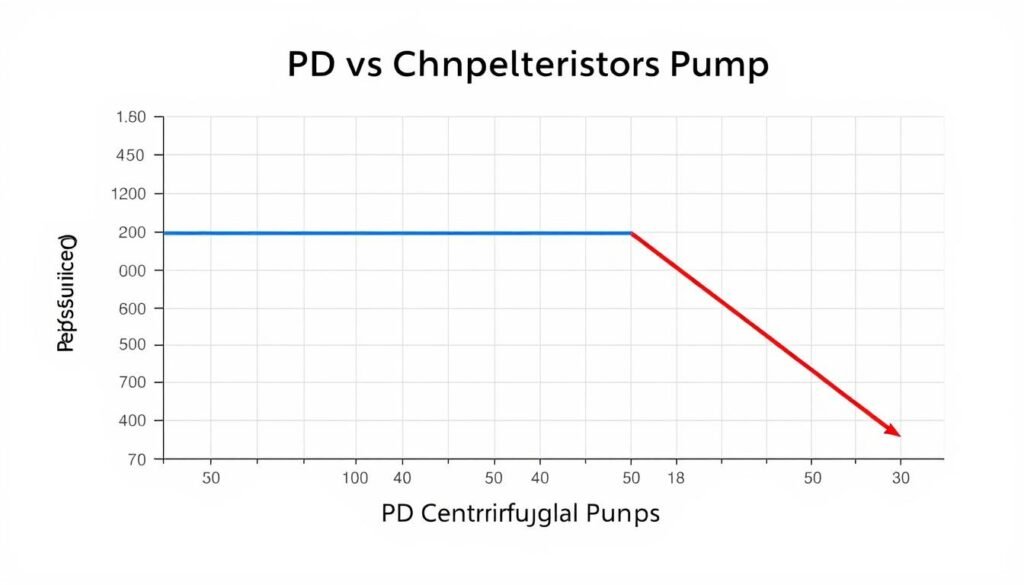

Flow characteristic graph showing how positive displacement pumps maintain constant flow regardless of pressure, while centrifugal pump flow decreases as pressure increases

Performance Comparison: Which Pump Does What Best?

| Performance Factor | Positive Displacement Pump | Centrifugal Pump |

| Flow Rate Consistency | Consistent regardless of pressure | Varies with pressure changes |

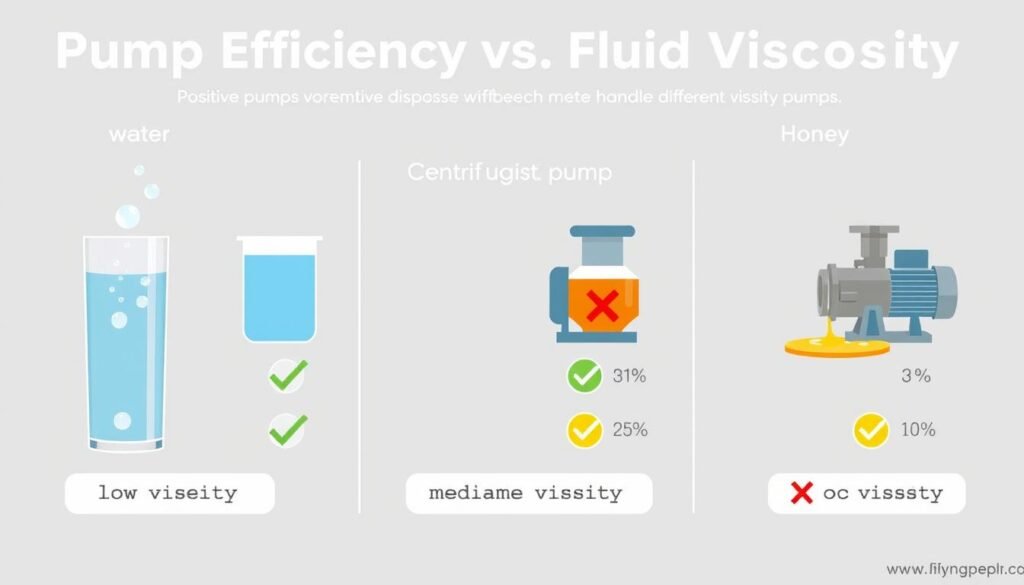

| Viscosity Handling | Excellent with thick fluids | Efficiency drops with viscous fluids |

| Pressure Capability | High pressure possible | Limited pressure range |

| Flow Rate Range | Lower flow rates | Higher flow rates possible |

| Efficiency with Thin Fluids | Good but may be oversized | Excellent efficiency |

| Suction Lift Ability | Good self-priming capability | Limited unless specially designed |

| Maintenance Requirements | More moving parts, higher maintenance | Fewer moving parts, lower maintenance |

Viscosity comparison showing how positive displacement pumps maintain efficiency with thicker fluids while centrifugal pumps perform best with water-like fluids

Real-World Applications: Where Each Pump Excels:

Centrifugal Pump Applications:

1). Municipal Water Supply:

- Centrifugal pumps are the workhorses of municipal water systems, where they move large volumes of clean water at relatively low pressure. Their high flow rates and efficiency with thin fluids make them perfect for transferring water from treatment plants to homes and businesses.

Why centrifugal works best here: The water’s low viscosity and the need for high volume flow at moderate pressure make centrifugal pumps the most efficient and cost-effective choice.

Positive Displacement Pump Applications:

2). Food Processing: Syrup and Sauce Production:

- Positive displacement pumps excel in food processing facilities where thick syrups, chocolate, and sauces need to be moved with precise flow control. These viscous materials would significantly reduce the efficiency of centrifugal pumps, but positive displacement pumps maintain consistent flow regardless of the thickness.

Why positive displacement works best here: The high viscosity of syrups and sauces requires a pump that maintains efficiency with thick fluids and provides precise dosing control.

3). Cooling Tower Circulation:

- Industrial cooling towers rely on centrifugal pumps to circulate large volumes of water through heat exchangers and cooling systems. The consistent flow of water at moderate pressures is perfectly suited to centrifugal pump capabilities.

Why centrifugal works best here: The need for high flow rates of low-viscosity water at moderate pressure makes centrifugal pumps more efficient and economical for cooling applications.

4). Oil Field Operations:

- In oil fields, positive displacement pumps are essential for moving crude oil, drilling mud, and other high-viscosity fluids. These pumps maintain their efficiency even when pumping thick, abrasive slurries that would quickly reduce the performance of centrifugal pumps.

Why positive displacement works best here: The high viscosity of crude oil and drilling fluids, combined with the need for consistent flow regardless of pressure variations, makes positive displacement pumps the optimal choice.

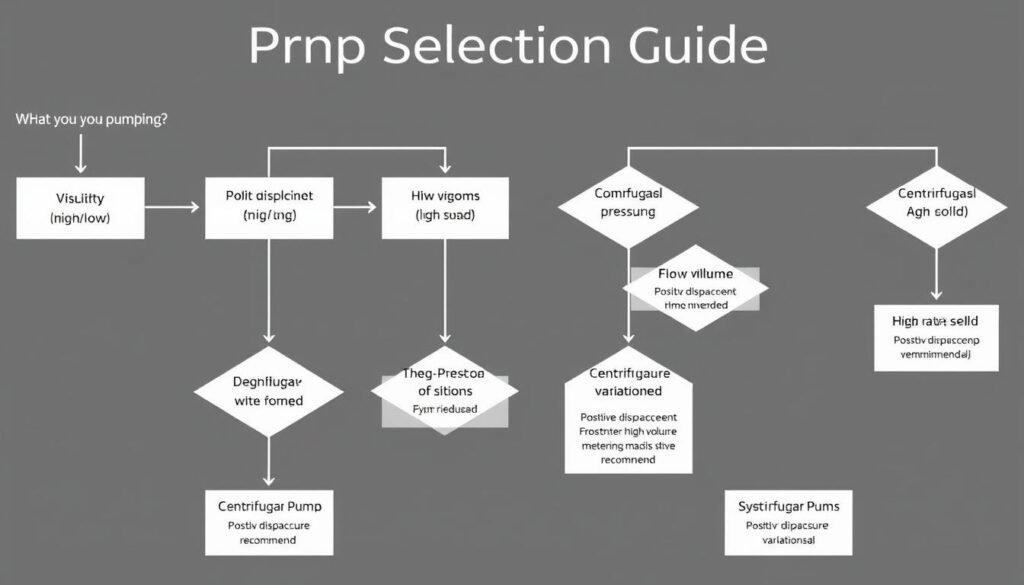

Pump Selection Guide: Making the Right Choice

Selecting between a positive displacement pump and a centrifugal pump depends on several key factors. Use this simplified decision guide to point you in the right direction:

Choose a Centrifugal Pump When:

- You need to move large volumes of fluid quickly

- Your fluid has low viscosity (like water)

- Flow rate precision is less critical

- You want lower initial and maintenance costs

- Your system operates at relatively constant pressure

- Fluid is clean with minimal solids

Choose a Positive Displacement Pump When:

- You’re pumping thick, viscous fluids

- Precise, consistent flow rate is required

- Your system needs high pressure capability

- You need good suction lift capability

- Your fluid contains solids or is abrasive

- System pressure varies significantly

Decision flowchart to help determine which pump type best suits your specific application requirements

Maintenance Considerations:

1). Centrifugal Pump Maintenance:

- Fewer moving parts generally means less maintenance

- Regular inspection of impeller for wear or damage

- Bearing lubrication according to manufacturer schedule

- Seal replacement when leakage occurs

- Monitor for unusual noise or vibration

2). Positive Displacement Pump Maintenance:

- More moving parts typically require more frequent maintenance

- Regular inspection of internal components for wear

- More frequent seal replacement due to higher pressures

- Lubrication of gears, bearings, and other moving parts

- Check valve inspection and cleaning

Conclusion: Choosing the Right Pump for Your Needs:

- The choice between a positive displacement pump and a centrifugal pump isn’t about which is “better” overall—it’s about which is better suited for your specific application. Consider your fluid properties, required flow rates, pressure needs, and maintenance capabilities when making your selection.

- For thin fluids and high-volume applications, centrifugal pumps often provide the most efficient and economical solution. For viscous fluids, precise metering, or high-pressure applications, positive displacement pumps are typically the better choice.

- Remember that many facilities benefit from using both pump types for different applications. Understanding the strengths and limitations of each pump type will help you make informed decisions that optimize your operations.